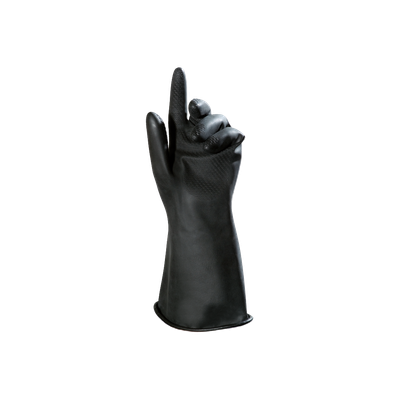

UltraNeo 420

Extremely supple with freedom of movement for standard chemical protection

-

CAT. 3

0334

0334

-

2121X

2121X

-

Type A

ALMNST

ALMNST

-

Specific advantages

Comfort

Comfort

- Freedom of movement, due to the supple quality of the neoprene and the comfort of the cotton flock-lining

Productivity

Productivity

- Good grip due to the embossed texture

Care for the environment

Care for the environment

- Plastic packaging optimized

- Recycled material in the packaging: 30 %

Applications

Automotive/mechanical industry

- Electric accumulator and battery manufacturing

Chemical industry

- Handling, loading and unloading of chemicals

Other industries

- Industrial cleaning, maintenance

- Preparation of industrial glues

- Spreading fertilizer

Product detail

| Material | Polychloroprene and natural latex |

|---|---|

| Colour | black |

| Interior finish | Flocked |

| Exterior finish | Embossed texture |

| Length (cm) | 32 |

| Thickness (mm) | .75 |

| Size | 6 7 8 9 10 |

| Packaging | 12 pairs/bag 72 pairs/carton |

Chemical chart

OVERALL CHEMICAL PROTECTION RATING

Protection rating is determined by taking into account the effects of both permeation and degradation in an attempt to provide users with an overall protection guideline when using our glove products against specific chemicals.

Meaning of the colours :

The chemical test data and overall chemical protection rating should not be used as the absolute basis for glove selection. Actual in-use conditions may vary glove performance from the controlled conditions of laboratory tests. Factors other than chemical contact time

| Chemical Product | CAS # | Breakthrough time (minutes) |

Permeation level |

Standard | Degradation level |

Rating |

|---|---|---|---|---|---|---|

| 1-Octanol 99% | 111-87-5 | 217 | 4 | ASTM F739 | 4 |

|

| 1,1,1-Trichloroethane 99% | 71-55-6 | 18 | 1 | EN 374-3:2003 | 1 |

|

| 2-Butoxyethanol (Butyl Cellusolve) 99% | 111-76-2 | 100 | 3 | EN 374-3:2003 | 3 |

|

| 2-Nitropropane 99% | 79-46-9 | 26 | 1 | EN 374-3:2003 | 3 |

|

| 2-Propanol (Isopropanol) 99% | 67-63-0 | 286 | 5 | EN 374-3:2003 | 4 |

|

| Acetic acid 10% | 64-19-7 | >480 | 6 | EN 16523-1:2015 | 4 |

|

| Acetic acid 50% | 64-19-7 | >480 | 6 | EN 16523-1:2015 | 4 |

|

| Acetic acid 99% | 64-19-7 | 391 | 5 | EN 16523-1:2015 | 4 |

|

| Acetone 99% | 67-64-1 | 15 | 1 | EN 374-3:2003 | 4 |

|

| Acetonitrile 99% | 75-05-8 | 11 | 1 | EN 374-3:2003 | 4 |

|

| Butyl Acetate 99% | 123-86-4 | 22 | 1 | EN 374-3:2003 | 1 |

|

| Cyclohexane 99% | 110-82-7 | 38 | 2 | EN 374-3:2003 | 3 |

|

| Dichloromethane (Methylene Chloride) 99% | 75-09-2 | 3 | 0 | EN 374-3:2003 | 1 |

|

| Diethylamine 98% | 109-89-7 | 7 | 0 | EN 374-3:2003 | 1 |

|

| Dimethylformamide 99% | 68-12-2 | 42 | 2 | EN 374-3:2003 | 4 |

|

| Dimethylsulfoxide 99% | 67-68-5 | >360 | 5 | EN 374-3:2003 | 4 |

|

| Ethanol 95% | 64-17-5 | 372 | 5 | EN 16523-1:2015 | 4 |

|

| Ethyl acetate 99% | 141-78-6 | 12 | 1 | EN 374-3:2003 | 3 |

|

| Formaldehyde 37% | 50-00-0 | >480 | 6 | EN 16523-1:2015 | 4 |

|

| Hydrochloric acid 10% | 7647-01-0 | >480 | 6 | EN 374-3:2003 | 4 |

|

| Hydrochloric acid 35% | 7647-01-0 | >480 | 6 | EN 374-3:2003 | 4 |

|

| Hydrofluoric Acid 40% | 7664-39-3 | >480 | 6 | EN 16523-1:2015 | NT |

|

| Hydrofluoric Acid 49% | 7664-39-3 | >480 | 6 | EN 374-3:2003 | NT |

|

| Hydrogen fluoride Anhydrous 99% Gas | 7664-39-3 | 25 | 1 | ASTM F739 | NT |

|

| Hydrogen peroxide 30% | 7722-84-1 | >480 | 6 | EN 16523-1:2015 | 4 |

|

| Methanol 99% | 67-56-1 | 226 | 4 | EN 16523-1:2015 | 4 |

|

| Methyl Ethyl Ketone (2-Butanone) 99% | 78-93-3 | 9 | 0 | EN 374-3:2003 | 2 |

|

| Methyl methacrylate 95% | 80-62-6 | 9 | 0 | EN 374-3:2003 | 2 |

|

| Methylisobutylketone 99% | 108-10-1 | 20 | 1 | EN 374-3:2003 | 2 |

|

| n-Heptane 99% | 142-82-5 | 73 | 3 | EN 16523-1:2015 | 3 |

|

| n-hexane 95% | 110-54-3 | 30 | 1 | ASTM F739 | 4 |

|

| N-methyl-2-Pyrrolidone 99% | 872-50-4 | 101 | 3 | EN 16523-1:2015 | 3 |

|

| N-N dimethyl acetamide 99% | 127-19-5 | 32 | 2 | ASTM F739 | 3 |

|

| Naphtha, Hydrotreated Heavy mixture | 64742-48-9 | 113 | 3 | EN 374-3:2003 | 4 |

|

| Nitric acid 10% | 7697-37-2 | >480 | 6 | EN 374-3:2003 | 4 |

|

| Nitric acid 20% | 7697-37-2 | >480 | 6 | EN 374-3:2003 | 4 |

|

| Nitric acid 40% | 7697-37-2 | >480 | 6 | EN 374-3:2003 | 4 |

|

| Nitric acid 50% | 7697-37-2 | >480 | 6 | EN 374-3:2003 | 4 |

|

| Nitric acid 65% | 7697-37-2 | >480 | 6 | EN 16523-1:2015 | 4 |

|

| Nitric acid 68% | 7697-37-2 | >480 | 6 | EN 374-3:2003 | 4 |

|

| Nitrobenzene 99% | 98-95-3 | 41 | 2 | ASTM F739 | 2 |

|

| Phosphoric acid 75% | 7664-38-2 | >480 | 6 | EN 374-3:2003 | 4 |

|

| Sodium hydroxide 20% | 1310-73-2 | >480 | 6 | EN 374-3:2003 | 4 |

|

| Sodium hydroxide 40% | 1310-73-2 | >480 | 6 | EN 374-3:2003 | 4 |

|

| Sodium hydroxide 50% | 1310-73-2 | >480 | 6 | EN 374-3:2003 | 4 |

|

| Styrene 99% | 100-42-5 | 12 | 1 | EN 374-3:2003 | 1 |

|

| Sulfuric acid 10% | 7664-93-9 | >480 | 6 | EN 374-3:2003 | 4 |

|

| Sulfuric acid 40% | 7664-93-9 | >480 | 6 | EN 374-3:2003 | 4 |

|

| Sulfuric acid 50% | 7664-93-9 | >480 | 6 | EN 374-3:2003 | 4 |

|

| Sulfuric acid 96% | 7664-93-9 | 204 | 4 | EN 16523-1:2015 | 4 |

|

| t-Butyl Methyl Ether 98% | 1634-04-4 | 18 | 1 | EN 374-3:2003 | 2 |

|

| Tetrachloroethylene (Perchloroethylene) 99% | 127-18-4 | 11 | 1 | EN 374-3:2003 | 1 |

|

| Tetrahydrofurane 99% | 109-99-9 | 7 | 0 | EN 374-3:2003 | 1 |

|

| Toluene 99% | 108-88-3 | 6 | 0 | EN 374-3:2003 | 1 |

|

| Trichloroethylene 99% | 79-01-6 | 6 | 0 | EN 374-3:2003 | 1 |

|

| Vinyl acetate 99% | 108-05-4 | 7 | 0 | EN 374-3:2003 | 2 |

|

| Xylene 99% | 1330-20-7 | 10 | 0 | EN 374-3:2003 | 1 |

|

*not normalized result

More gloves

Get in touch

If you would like to ask us a commercial question about our products or if you would like to have more technical information about our gloves and their use, please fill out one of the forms proposed below.

Standards

All standardsDocumentation

Mapa Professional 2026 Catalog

Online readingEnglish - 2026 edition